Article

My foam cannon from another brand is not working properly

The simple answer to the problem may be the wrong nozzle size or dirt in the nozzle. To resolve this, it is recommended to test different nozzles and foam cannons, as well as to clean the nozzle thoroughly.

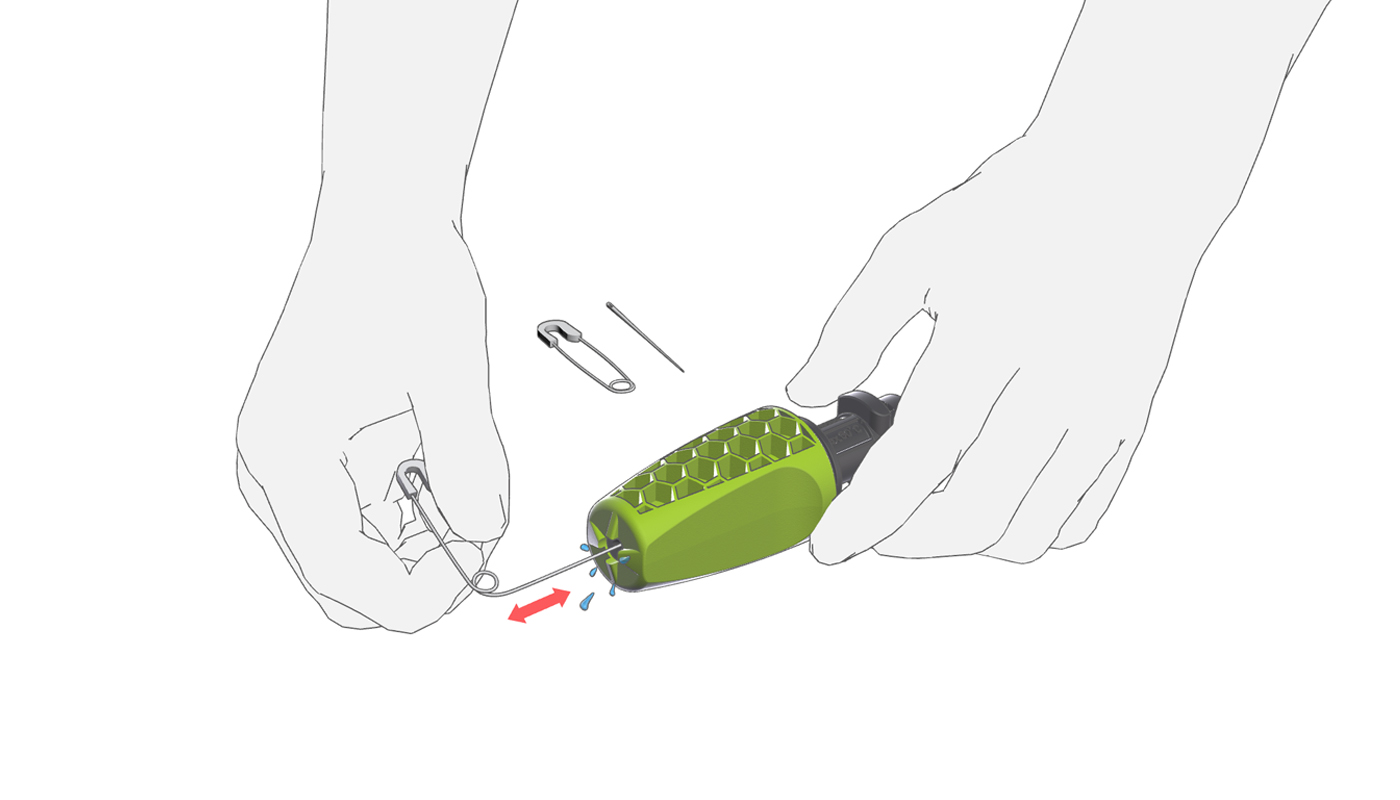

Dirt: A partially blocked nozzle may be the cause of issues with a foam cannon that previously worked fine. This could be due to something as small as a grain of sand. The problem can often be resolved by rinsing the nozzle in hot water or using a needle to clean it.

Nozzle Sizes

For a high-pressure washer to provide optimal cleaning effectiveness, different pump sizes require their own nozzles calibrated to specific sizes.

Our nozzles are color-coded to distinguish which washers they are compatible with:

Green: P30-P60

Blue: P70-P80

Purple: P90

If the machine "hunts" during spraying, it may be because the nozzle is too small. Test with different types of accessories to determine if this is the problem. If the machine operates normally with some nozzles, the fault lies in the accessory, not the machine itself. A nozzle that is too small causes the machine to reach maximum pressure and shut off, then turn back on when the pressure drops. This results in a frequent "hunting sound" or intermittent reaction from the pump.

Foam nozzles from AVA are specially tailored to the different models, while other brands often have universal nozzles. These can vary in size, even though they are intended for the same type of foam cannon. This can affect performance.

Common Causes: A marginally too small nozzle can work at low voltage in the home but fail at higher voltage. This can vary depending on the location relative to the fuse box and the use of an extension cord. A change in equipment such as a gun, lance, or hose can also affect, but if other accessories work, it is probably the nozzle that is the problem.

Technical Specifications: AVA uses 1.35 nozzles in its foam cannons. Other brands often range from 1.21 to 1.32, although they are meant to be 1.25 or 1.3. We have seen significant variations in these, which can explain why some work and others do not. By using a larger nozzle, such as 1.40, these problems can be avoided. Smaller sprayers handle this increase well, therefore we now only deliver one nozzle size up to model P80.

High-pressure washers have a pump that at a given rpm has a fixed amount of water. By introducing a restriction such as a nozzle, the pump has to work harder, which increases the pressure. The pressure sensor in AVA high-pressure washers is electromechanical and adjusts according to the pressure. Variations in temperature and material tolerances can cause foam cannons to perform differently on different machines. Our equipment accommodates this variation, and only a few of the nozzles will be near the maximum working pressure.